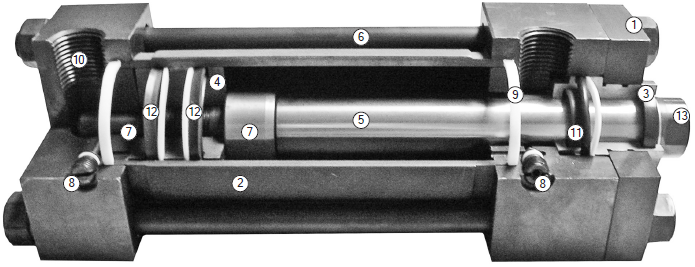

SERIES HHD FEATURES

See "How to Order" guide - page 5.

See "Pressure Rating" notes page 4.

See "Pressure Rating" notes page 4.

- HEAD/CAP- Precision machined steel head and cap provide close concentricity and accurate alignment between piston, tube, piston rod and rod bearing.

- CYLINDER BARREL- Damage resistant, heavy wall steel tubing, honed to an 8 to 16 micro finish for low frictional drag and maximum seal and piston bearing life.

- ROD CARTRIDGE- Extra long, high strength bronze gland provides maximum bearing support and wear resistance. With certain exceptions, a removable retainer allows for gland removal without cylinder disassembly.

- PISTON- One piece fine grained cast iron piston provides maximum strength and protection against shock loads. Anaerobic adhesive is used to permanently lock and seal the piston to the rod.

- PISTON ROD- High strength damage resistant piston rod provides 100,000 PSI minimum yield material in 5/8” through 4 1/2” diameters. Larger diameters vary between 50,000 and 75,000 PSI minimum yield material. All rods are case hardened to 50-55 RC and hard chrome plated to provide maximum wear life. Stainless steel is also available.

- TIE RODS- 100,000 to 125,000 PSI minimum yield steel, pre-stressed for fatigue resistance, and roll threaded for added strength.

- CUSHIONS- Head cushion sleeve and rear

cushion spear are machined to close tolerances to provide a gradual deceleration and reduced shock at end of stroke.

- CUSHION NEEDLE ADJUSTMENT AND BALL CHECK- Flush mounted captive cushion adjustment allows for safe cushion adjustment under pressure. Special tip design and fine threads allow for precise adjustment over a broad range of operations. Cushion ball check allows for fast break-away under full power.

- TUBE END SEALS- Extrusion resistant Teflon® material is compatible with virtually all fluids and can operate in temperatures to 500°F.

- PORTS- SAE ports are standard and can be rotated to any 90 degree position in relation to each other and the mounting. NPTF ports are optional at no extra charge.

- ROD SEAL- Twin lip urethane rod seal is pressure energized and wear-compensating for long, leak-free service. Viton® seals are optional.

- PISTON SEALS- Pressure energized nitrile U-cups with back-up rings are standard. Step cut cast iron rings and Viton® seals are optional.

- ROD WIPER- Nitrile double lip rod wiper acts as a secondary seal while keeping out dirt, dust and other contaminants. Optional Viton® wiper is available for fluid compatibility or temperatures to 400°F. Metallic scrapers and low friction wipers are also available.

2