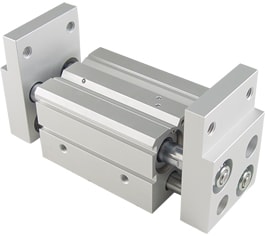

FKHL Series Wide Parallel Grippers

The FKHL Series are parallel pneumatic grippers. The compact design of the FKHL Series is ideal for various size work-piece applications. A dual piston mechanism synchronized by a rack-and-pinion delivers high grip force with great precision.

Features:

- Available in 5 bore sizes: 10mm, 16mm, 20mm, 25mm, and 32mm

- Magnetic piston is standard

- Standard rod scrapers for dust and debris protection

- Oil impregnated sleeve bearings encased in steel on all units

- Integrated sensor slots in the gripper body enable easy mounting of sensors for both “open” and “closed” position sensing

- Aluminum gripper body is hard-coated to ensure abrasion and to combat corrosion

- No additional lubrication is required

Specifications:

- Operating pressure ranges from 15 psi to 87 psi

- Operating media is compressed air

- Repeatability: +/- 0.2mm

- Effective Gripping Force at 72 psi:

– 10mm Bore: 3.1 lbf

– 16mm Bore: 10.1 lbf

– 20mm Bore: 16.6 lbf

– 25mm Bore: 29.4 lbf

– 32mm Bore: 51.2 lbf

The FKA Series Angular Pneumatic Grippers

The compact design of the FKHC Series angular pneumatic gripper is ideal for handling small parts in confined areas. The FKA Series was designed with tight budgets in mind.

Features:

- Available in 4 bore sizes: 10mm, 16mm, 20mm, and 25mm

- Magnetic piston is standard

- Integrated sensor slots in the gripper body enable easy mounting of sensors for both “open” and “closed” position sensing

- Aluminum gripper body is hard-coated to ensure abrasion and to combat corrosion

- No additional lubrication is required

Specification:

- Operating pressure ranges from 15 psi to 100 psi

- Operating media is compressed air

- Opening: -10° to 30°

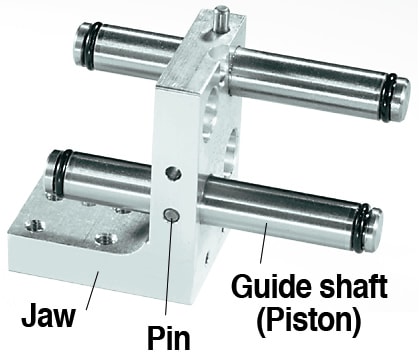

The SPG Series Parallel Pneumatic Grippers.

The SPG Series encompasses a unique design. The jaws and the pistons are an integral assembly. These grippers have just three moving parts, therefore the design is both compact and lightweight.

Jaw Construction

A pair of ground, stainless steel guide shafts (which double as air pistons) are press fit and pinned to each gripper jaw. Shafts are placed diagonally and spaced far apart for maximum jaw stability.

Porting block completes the housing

No troublesome gibs to wear or adjust. Four dowel pins align the porting block perfectly with the cylinder blocks. Eight high-performance linear bearings guide the four pistons through the entire length of the gripper body. Centering accuracy is maintained to .002″ and side play is .0015″ or less per jaw. Metal nameplates provide coverage and protection on both sides.

FKA Series Pneumatic Angular Grippers

FKA Series Pneumatic Angular Grippers